ID Card Printing Technologies

Choose the Right Printing Method for Your Identity Needs

Stravata Solutions offers two powerful ID card printing technologies—Retransfer Printing and Direct-to-Card (DTC) Printing—each designed to meet specific needs based on security level, durability, visual quality, and cost. This page helps you understand the core differences and explore which method is right for your organization.

Retransfer printing offers superior print quality and edge-to-edge coverage, making it ideal for high-security environments, smart card printing, and long-lasting credentials. It uses a two-step process that prints onto a clear film before bonding to the card surface—ensuring consistent results even on uneven or embedded cards.

deal for:

Government agencies

Smart card programs

High-volume or extended-use ID credentials

Flawless Visual Quality. Industrial Strength. Stravata Precision.

Retransfer Printing

Fast. Efficient. Perfect for Everyday Credentialing.

Direct-to-Card (DTC) Printing

Ideal for:

Schools and universities

Temporary employee or visitor badges

Event passes and internal ID programs

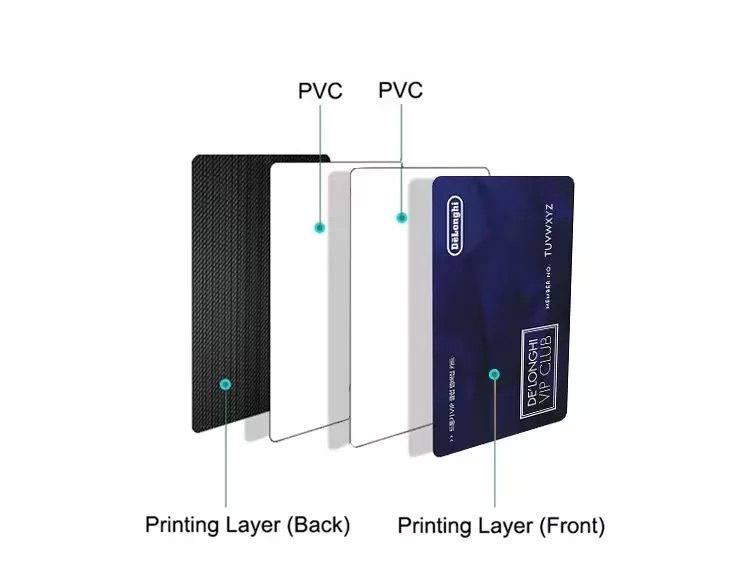

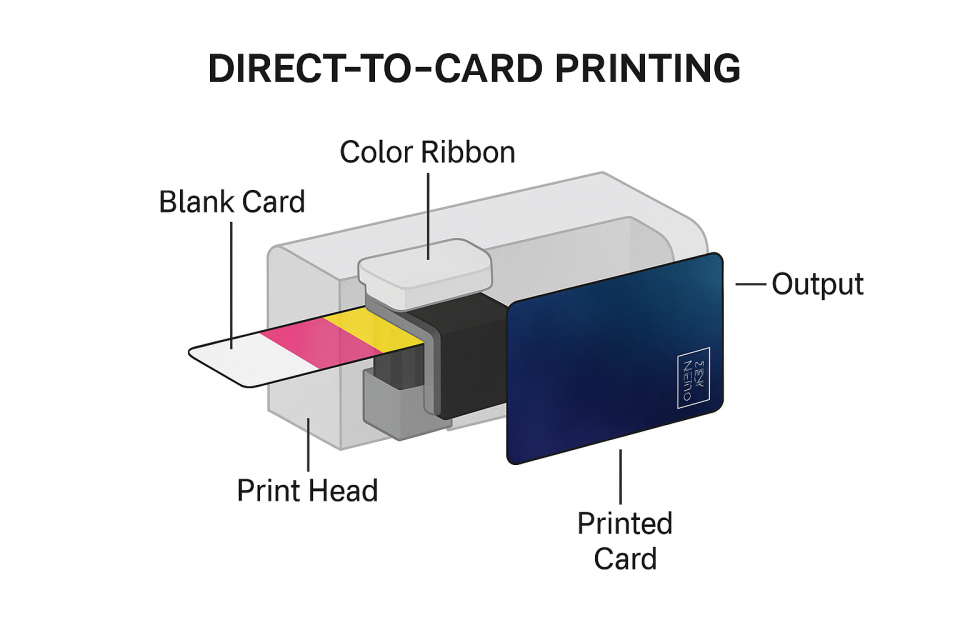

Understanding Card Structure

The image above illustrates the layered construction of a standard PVC ID card. Each card consists of multiple layers:

Printing Layer (Front): This is where your primary design elements—such as logos, photos, names, and barcodes—are printed. For DTC printing, ink is applied directly here; for retransfer printing, a clear film is thermally bonded to this surface.

PVC Core Layers: These central white layers form the durable body of the card. They provide structural integrity and flexibility for encoding technologies (e.g., magnetic stripes, chips) without sacrificing print compatibility.

Printing Layer (Back): The back of the card holds secondary information, branding, and optional encoding (e.g., magnetic stripe data).

This layered approach allows Stravata to deliver resilient, high-quality credentials capable of supporting multiple print technologies, security features, and branding options—all while maintaining a professional finish and long-term durability..

Which Printing Method Is Right for You?

Every organization has unique needs. Whether you need cards that stand up to rugged daily use or fast turnaround for internal badge programs, we’ll guide you to the best fit

• Print Quality

Retransfer Printing: High-resolution, full-bleed edge-to-edge images

Direct-to-Card Printing: Standard resolution, minor edge gaps possible

• Durability

Retransfer Printing: Excellent, especially with lamination

Direct-to-Card Printing: Moderate, best for short to medium-term use

• Security Add-Ons

Retransfer Printing: Supports UV ink, holograms, laser engraving

Direct-to-Card Printing: Supports basic barcodes, magnetic stripes

• Material Compatibility

Retransfer Printing: Ideal for Teslin, smart cards, PET/PVC composites

Direct-to-Card Printing: Best for standard PVC and composite PVC cards

• Cost Per Card

Retransfer Printing: Higher per card due to materials and processing

Direct-to-Card Printing: Lower per card, ideal for bulk and short-term use

• Speed

Retransfer Printing: Moderate print speed

Direct-to-Card Printing: Fast, ideal for on-site or on-demand printing

Need Help Choosing?

Stravata offers free consultations to help you select the best printing method for your security, budget, and workflow requirements.

Tagline

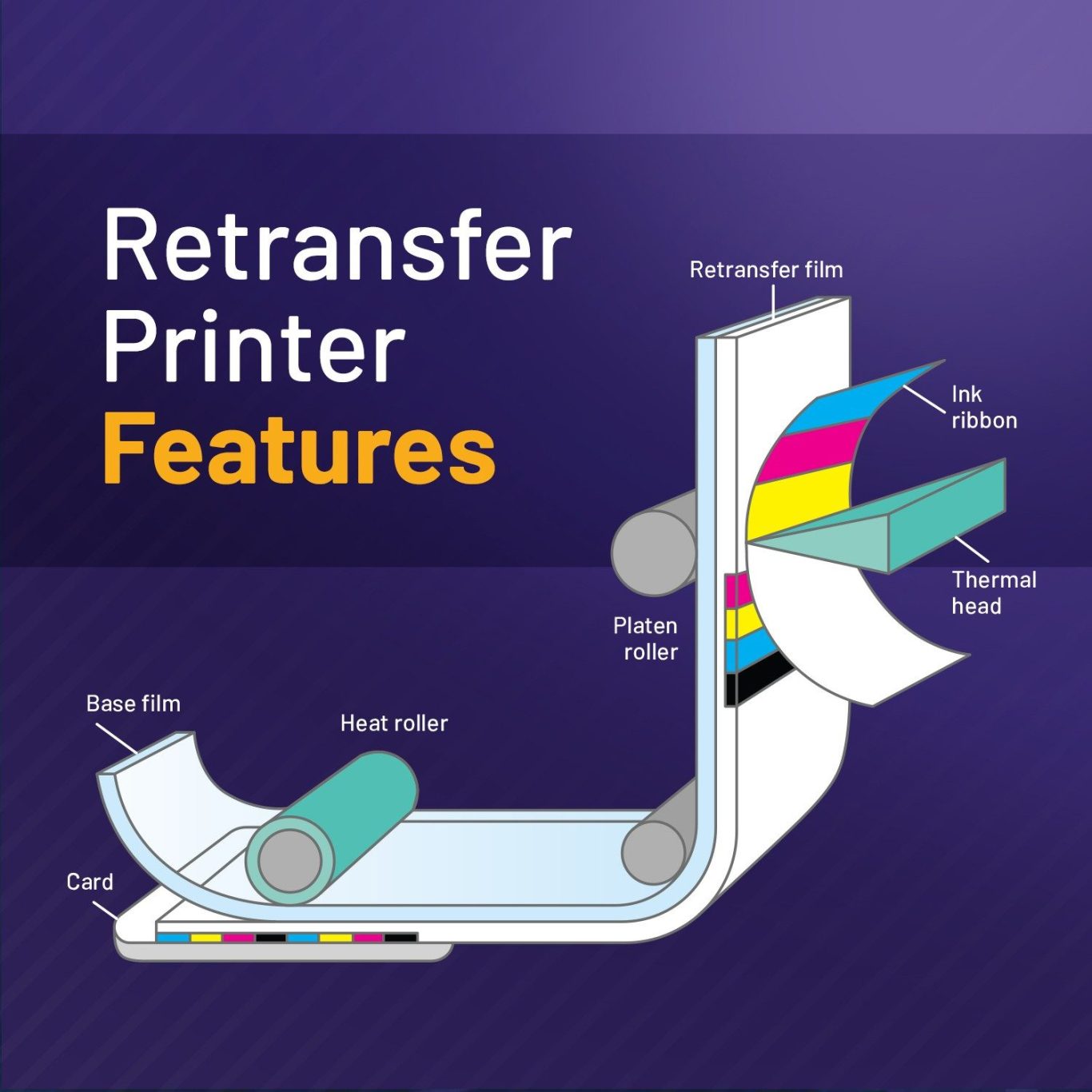

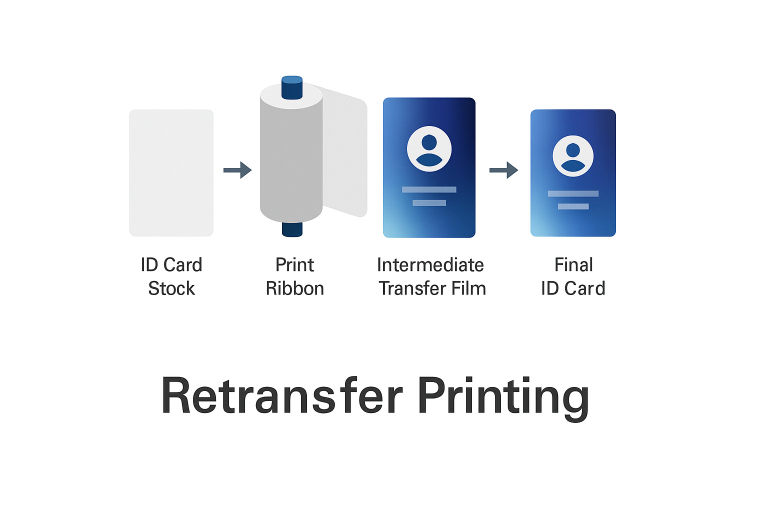

How Retransfer Printing Works

Step 1: High-Resolution Image Creation

Retransfer printing starts by reverse-printing your card design onto a clear transfer film using dye sublimation. This film captures vibrant, high-resolution images and security features with excellent precision.

Step 2: Film Transfer to Card Surface

The printed film is thermally bonded to the surface of the card using heat and pressure. This indirect method allows for edge-to-edge printing on complex surfaces like embedded chips or textured laminates.

Step 3: Seamless Durability & Alignment

Since the printhead never contacts the card, wear and tear are reduced. Alignment stays consistent, even across large batches—perfect for high-security or high-visibility credentials.

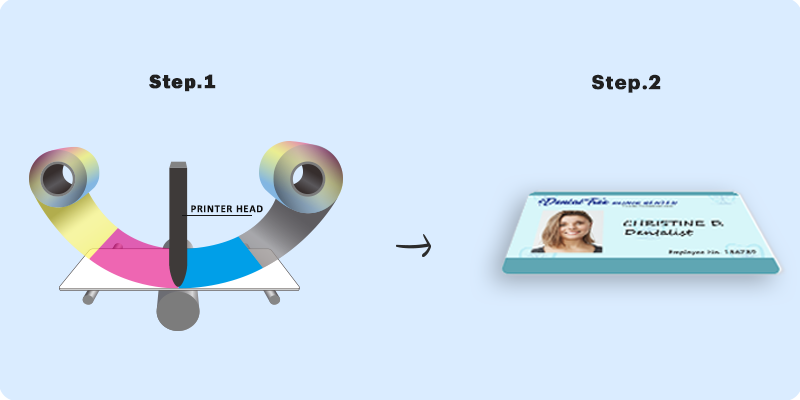

How Direct-to-Card Printing Works

Tagline

Step 1: Image Rendering

The DTC printer starts by processing the digital design—typically a combination of ID photo, name, title, barcode, and background—through its print driver, preparing the file for color separation and layout.

Step 2: Dye Sublimation Transfer

Using a multicolor ribbon (usually CMYK), the printer applies heat via a printhead that comes into direct contact with the card. This process converts solid dye into gas and transfers it directly to the card's surface in precise, pixel-level resolution.

Step 3: Overlay Application

After the image is applied, a clear overlay panel (O-panel) is usually added to protect the printed surface from minor abrasion and UV damage. This overlay also helps extend the card's visual lifespan.

Step 4: Output & Readiness

The finished card is ejected from the printer and is ready for use immediately. Cards printed with DTC can be encoded with magnetic stripes during the same print cycle if needed.

This direct method offers rapid production with a lower cost per card, making it especially suitable for schools, events, internal badges, and any setting where visual branding and turnaround speed matter more than advanced physical security.

Stravata Solutions delivers both retransfer and direct-to-card printing options under one roof—giving you the flexibility to choose the right technology for every job. From high-security credentials with advanced protection to fast-turnaround cards for internal use, our team is ready to support your ID programs at every level.

One Source, Two Powerful Printing Solutions

Bringing It All Together

Our promise

Our highly qualified experts will complete any task fast and reliably.

Get in touch today to find the perfect solution tailored to your organization’s unique needs. to help you select the best printing method for your security, budget, and workflow requirements.

©Copyright. All rights reserved. 2025

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.